Finding the right laser printer for t shirts can transform your custom apparel game. Here’s what you need to know:

Best Laser Printers for T-Shirt Transfers:

- Brother HL-L2300D – Excellent for monochrome designs and mass production (30 ppm)

- HP LaserJet Pro M454dw – Reliable color printing with professional results

- OKI Pro6410 NeonColor – Features white toner for vibrant prints on dark fabrics

- Canon imageCLASS LBP6030w – Budget-friendly option for small batches

Key Requirements:

- Minimum 600×600 DPI resolution (1200×1200 DPI preferred)

- Paper weight handling up to 300 g/m² (110 lb)

- Straight-through paper path to prevent jams

- Compatible with laser transfer paper

Custom t-shirt printing is a booming market, and laser printers offer an ideal entry point for small businesses and hobbyists. Unlike inkjet printers that use liquid ink, laser printers use heat-resistant toner that creates crisp, durable transfers. The process involves printing a design onto special heat transfer paper and using a heat press to bond it permanently to the fabric, resulting in brighter colors and cleaner edges.

Why laser beats inkjet for t-shirts:

- Toner resists heat and water better than ink

- Faster printing speeds (up to 30 pages per minute)

- Lower cost per page for high-volume production

- Sharper text and graphics with no bleeding

Whether you’re creating promotional gear or starting a custom apparel business, the right laser printer helps produce professional-quality transfers that withstand multiple wash cycles.

Why Choose a Laser Printer for T-Shirt Transfers?

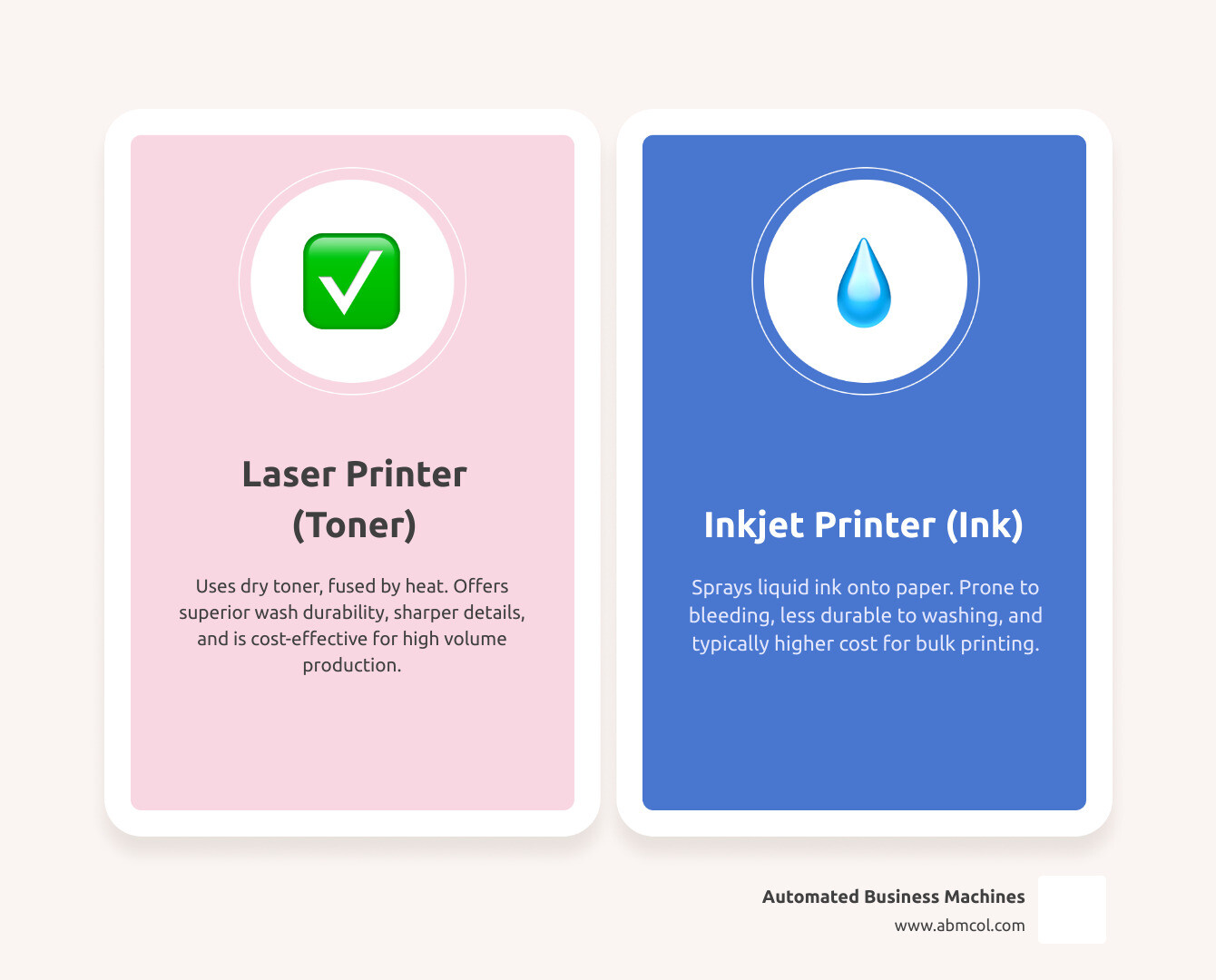

When creating custom t-shirts, the printer you choose is a game-changer. Among the many options—inkjet, sublimation, DTG (Direct-to-Garment)—the laser printer for t shirts stands out for its unique advantages in heat transfer methods. Unlike inkjet printers that spray liquid ink, laser printers use a dry, plastic-based powder called toner. This toner is melted and fused onto the paper, a core difference that is crucial for high-quality t-shirt transfers.

Toner vs. Ink: The Unsung Heroes of Durability

The primary difference lies in the materials: toner is a plastic powder, while ink is liquid. Toner is naturally more resistant to heat and water, creating a stable, crisp image that’s far less likely to bleed or fade during the heat transfer process or after washing. This stability leads to superior print quality, with incredible precision and sharpness for crisp edges and vibrant colors. Plus, laser printers are fast, with many models printing 30 pages per minute or more, a huge bonus for high-volume jobs.

For more in-depth knowledge on optimizing your transfer process, explore our Advanced Heat Transfer Solutions.

The Best Quality and Durability of Toner

Toner’s magic shines during the heat press stage. Because it’s fused onto the paper’s surface rather than soaking in, the resulting text and graphics are incredibly sharp with no bleeding. When transferred to a t-shirt, the design remains crisp and clear. Durability is essential for t-shirt designs, and laser-printed transfers are exceptionally tough. The heat-set toner becomes part of the fabric, resisting fading, cracking, or peeling. A well-executed laser transfer can easily handle over a dozen wash cycles with minimal wear, delivering a professional finish that keeps customers happy.

Cost and Efficiency: A Smart Investment

While the initial cost for a quality laser printer for t shirts and specialty toners (like white toner) can be higher, it’s an investment that pays off. The cost per page for toner is significantly lower than ink, making high-volume production more economical. You’ll change toner cartridges less frequently, reduce wasted prints from poor quality, and benefit from faster production times. This efficiency lowers overall operating costs and frees you to focus on designing and growing your business. While an inkjet’s lower price might be tempting, a laser printer’s speed and reliability are invaluable when orders start piling up.

Here’s a quick look at how laser and inkjet stack up for t-shirt transfers:

| Feature | Laser Printer for T-Shirts | Inkjet Printer for T-Shirts |

|---|---|---|

| Print Quality | Crisp, sharp, no bleeding; excellent for text and fine lines | Can be good for photos; prone to bleeding on transfer paper |

| Durability | High heat and water resistance; less fading/cracking after washes | Lower heat/water resistance; more prone to fading and cracking |

| Speed | Fast (20-30+ ppm); ideal for high-volume production | Slower (5-15 ppm); less efficient for bulk printing |

| Cost per Page | Low (3-5 cents); cost-effective for high volume | Higher (10-25 cents); can be expensive for frequent printing |

| Fabric Comp. | Excellent with laser transfer paper on various fabrics | Good with inkjet transfer paper, often best on cotton |

| Specialty Toner | White toner available for dark fabrics | No white ink option for opaque prints on dark fabrics |

Key Features of the Best Laser Printer for T Shirts

Choosing the right laser printer for t shirts means finding one with the specific features that make your custom apparel shine and last. Pinpointing the key specs is crucial for successful heat transfer printing.

Essential Specifications for a High-Quality Laser Printer for T Shirts

Look for these must-have features to ensure top-notch results:

- Print Resolution (DPI): For detailed images, a minimum of 600 x 600 dots per inch (dpi) is necessary. For the crispest text and smoothest graphics, aim for 1200 x 1200 dpi or higher.

- Paper Handling and Weight Compatibility: Heat transfer paper is thick and heavy. Your printer must handle paper weights up to 110 lb (or 300 g/m²) to feed the media smoothly without jamming.

- Straight-Through Paper Path: This feature is a lifesaver. It allows thick transfer paper to travel in a flat line through the printer, preventing jams and stopping toner from flaking off.

- Toner Compatibility: Use toners designed to adhere well to transfer paper and withstand the heat press. This applies to standard CMYK (Cyan, Magenta, Yellow, Black) and any specialty toners.

- Connectivity Options: Modern features like wireless printing, mobile compatibility, and fast Ethernet make it easy to print from any device, saving time and streamlining your workflow.

For a deeper dive into selecting the right hardware, check out our guide on the Best Laser Printers for Heat Transfer Paper.

Opening up Creativity with Color and White Toner

While a monochrome printer works for basic logos, a color laser printer releasees your creativity. Using CMYK toner cartridges, you can produce vibrant, full-color designs. However, to print on dark fabrics, white toner printers are essential. Standard printers can’t print white, so designs on dark shirts appear dull. A white toner printer lays down an opaque white layer, making your colors pop brightly on any color garment. This capability is a game-changer for any business offering a full range of custom apparel. Some specialty toners even offer fluorescent or glitter effects, making a laser printer for t shirts an incredibly powerful and versatile tool.

You might also find useful insights in our article about the Best Laser Printers for Cardstock Printing, as cardstock shares similar handling requirements with transfer paper.

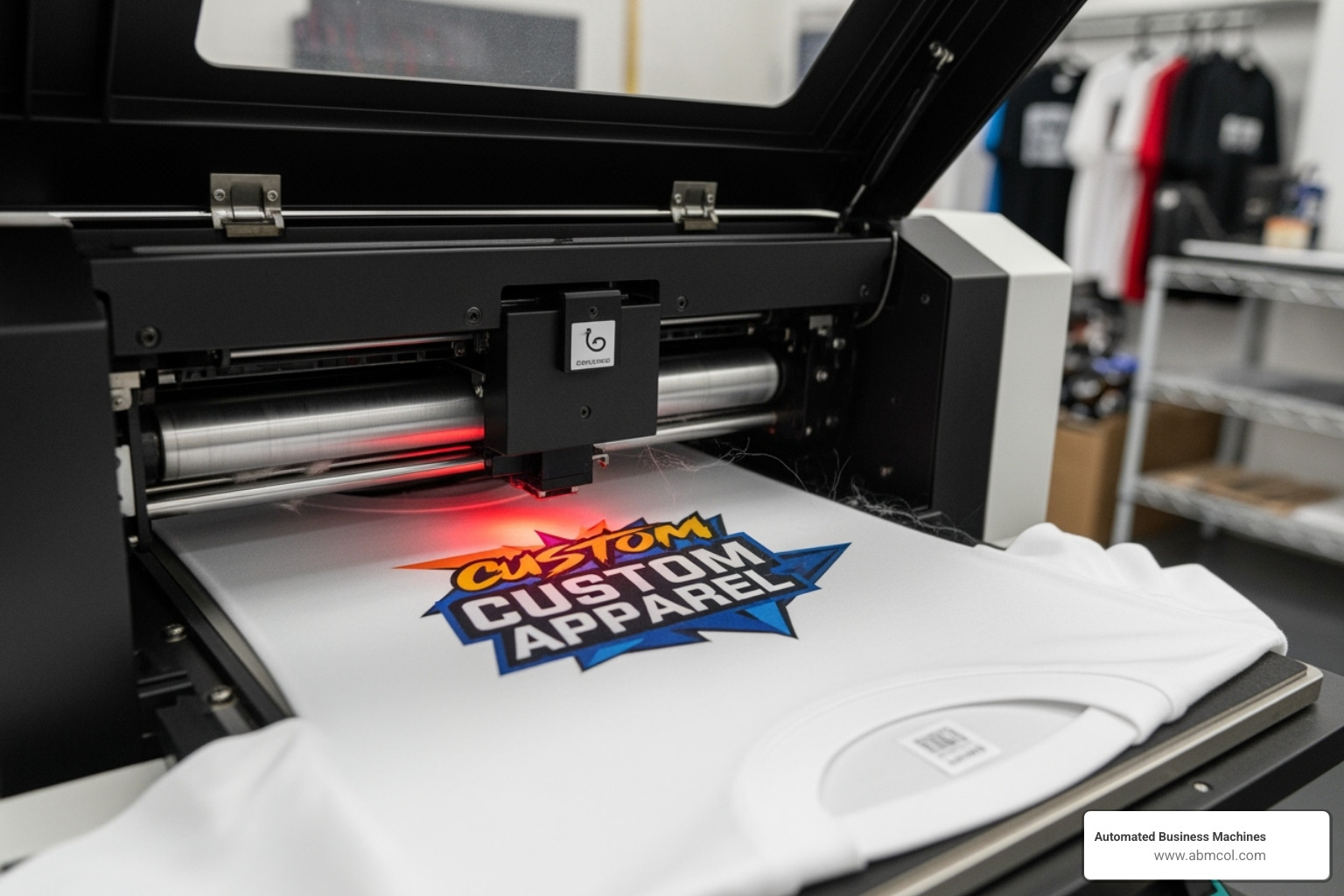

Your Step-by-Step Guide to Printing T-Shirts with a Laser Printer

Turning your digital designs into wearable art is a rewarding and straightforward process. Following these steps carefully will ensure you achieve professional-quality results with your laser printer for t shirts.

Step 1: Gather Your T-Shirt Printing Equipment

Having all your tools ready makes the process smooth and efficient. Here’s what you’ll need:

- Laser Printer: Loaded with the correct toner (CMYK or with white toner for dark fabrics).

- Heat Press Machine: Essential for permanent, professional results. A household iron will not provide the consistent heat and pressure required.

- Laser Transfer Paper: Use paper specifically designed for laser printers that matches your fabric color (light or dark). For more details, see our guide on Heat Press Transfer Paper Types.

- T-shirt: Quality cotton, polyester, or blend fabrics work best.

- Computer with Design Software: Your creative hub for preparing your artwork.

- Teflon Sheet: Protects your design and heat press while ensuring even heat distribution.

- Heat-Resistant Tape (Optional): Useful for securing the transfer paper precisely on the shirt.

- Scissors or Craft Cutter: For trimming your design before pressing.

Step 2: Prepare and Print Your Design

Careful preparation at this stage is key to a flawless final product.

- Create Your Design: Use graphic software to finalize your artwork.

- Mirror the Image: You must flip your image horizontally before printing. Otherwise, any text or asymmetrical designs will appear backward on the shirt.

- Adjust Printer Settings: In your printer’s menu, make the following changes:

- Paper Type: Select “Transfer Paper,” “Heavyweight,” or a similar setting to ensure the printer handles the thick media correctly.

- Print Quality: Choose “High Quality” or increase toner density for maximum vibrancy and durability.

- Duplex Printing: Make sure this feature is turned off.

- Print the Design: Load the laser transfer paper into the correct tray, ensuring the printable side is oriented properly (check paper instructions). Handle the printed sheet carefully to avoid smudging the toner.

Need more tips on printing on specialized media? Our guides, like the one on Best Photo Paper for Laser Printers, can offer some helpful insights.

Step 3: The Heat Press Transfer Process

This is the final step where your design is permanently applied to the garment.

- Pre-press the T-shirt: Place the shirt on the heat press and press for 5-10 seconds. This removes moisture and wrinkles, creating a smooth surface for the transfer.

- Position the Transfer: Carefully place your printed design onto the t-shirt. Check your paper’s instructions for correct orientation (usually face down).

- Apply Teflon Sheet: Cover the transfer paper with a Teflon sheet to protect your equipment.

- Set Heat Press: Adjust the temperature, time, and pressure according to the instructions provided with your transfer paper. Typical settings are 350-400°F (175-200°C) for 20-60 seconds with firm pressure.

- Press the Design: Close the press and start the timer.

- Peel the Paper: This step is critical and depends on your paper type. Hot peel papers require you to remove the backing immediately, while cold peel papers must cool completely first. Always follow the manufacturer’s instructions to avoid a ruined design.

Safety Precautions: Heat presses are extremely hot. Be cautious, use heat-resistant gloves if needed, ensure good ventilation, and never leave a hot press unattended.

Understanding the fabric types you’re working with can also make a big difference. Our Heat Transfer for Polyester Guide offers some extra insights that might come in handy.

Pro Tips for Durability and Care

Once you’ve pressed your custom t-shirts with your laser printer for t shirts, proper care is essential to ensure the designs last. Following a few pro tips can lift your results and maximize longevity.

Achieving Professional-Looking Results

Fine-tuning your process makes the difference between good and professional results. Here are key tips:

- Use Test Prints: Always test your settings on scrap fabric before printing on a final garment. This helps you dial in the perfect heat press temperature, time, and pressure.

- Proper Weeding: For two-step transfer papers (common with white toner), carefully weeding away excess film is critical for clean, crisp edges.

- Consistent Pressure: Ensure your heat press provides even pressure across the entire design to prevent peeling or cracking.

- Quality Materials: Use high-quality transfer paper designed for your specific laser printer and fabric type for the best durability.

- Calibrate Your Printer: Regularly calibrate your printer to maintain consistent and accurate colors.

How to Care for Your Laser-Printed T-Shirts

Proper care ensures your custom apparel can withstand dozens of washes without significant fading or cracking. Follow these washing and drying instructions for the best longevity expectations.

- Wait 24 Hours Before Washing: Allow the toner to fully cure and bond with the fabric before the first wash.

- Turn T-Shirt Inside Out: Protect the printed design from abrasion in the washing machine.

- Wash in Cold Water on a Gentle Cycle: Hot water and aggressive cycles can degrade the transfer. Use a mild detergent and avoid bleach or fabric softeners.

- Tumble Dry Low or Hang Dry: High heat from a dryer can damage the design. Air drying is the safest option.

- Never Iron Directly on the Print: If you must iron the shirt, turn it inside out or place a protective sheet over the design.

Following these steps will keep your custom t-shirts looking fantastic for a long time.

Frequently Asked Questions about Using a Laser Printer for T Shirts

Getting started with custom t-shirt printing can bring up a few questions. Here are answers to some of the most common ones.

Can I use a regular office laser printer for t-shirt transfers?

Yes, but with important considerations. A standard office laser printer for t shirts may work for occasional projects if it can handle heavy paper (at least 220 gsm) and has a straight-through paper path to prevent jams. Always check the manufacturer’s specifications for compatibility with heat transfer media. While a basic printer can work for simple jobs, models designed for heavy media and specialty toners (like white toner) will provide far more consistent and superior results for a serious business.

What’s the difference between transfer paper for light vs. dark fabrics?

This distinction is crucial for your final product’s appearance. Transfer paper for light fabrics is transparent, allowing the shirt’s color to show through in unprinted areas of the design. It’s ideal for white or pastel garments. In contrast, paper for dark fabrics has an opaque white background. This white layer acts as a base, ensuring your design’s colors appear vibrant and are not muted by the dark garment color.

Is a laser printer better than a DTG printer for t-shirts?

It depends on your goals, as each is the right tool for a different job. A laser printer for t shirts with transfer paper is an affordable and versatile entry point for startups and hobbyists. It’s flexible, allowing you to print on many materials beyond t-shirts (like mugs and signs) with excellent durability. Direct-to-Garment (DTG) printers apply ink directly to the fabric for a softer feel, but they require a much higher initial investment, more maintenance, and specialized pre-treatment. For small batches, diverse products, or home use, laser transfer is often the more practical and cost-effective choice.

Conclusion: Start Your Custom Apparel Journey

The world of custom t-shirt printing is full of creative possibilities, and a laser printer for t shirts is your key to entry. This technology stands out for its durable, heat-resistant toner, which produces crisp, vibrant designs that last wash after wash. This level of quality is what builds a loyal customer base.

For a small business or hobbyist, a laser printer is a smart investment. It’s efficient, fast, and versatile, allowing you to create not just t-shirts but a wide range of custom promotional items. It provides an excellent and cost-effective entry point into the custom apparel industry.

Here at Automated Business Machines, we are passionate about helping you succeed with advanced printing solutions that boost productivity and workflow. Our goal is to provide the right tools to turn your brilliant ideas into high-quality products. We’re here to help you build your business, one custom tee at a time.

Ready to turn your designs into reality? Explore our Products and Solutions today and let’s start printing amazing t-shirts together!