Advanced heat transfer solutions are revolutionizing how we manage thermal challenges across industries, from quantum computing to sustainable energy. These technologies move beyond traditional methods, using sophisticated engineering to maximize efficiency and minimize energy waste.

Key innovations include:

- Microchannel Heat Exchangers: Up to 85% smaller and lighter than conventional designs.

- Printed Circuit Heat Exchangers (PCHEs): Handle pressures over 600 bar with superior robustness.

- Dimpled Tube Technology: Increases heat transfer up to 16 times in laminar flow.

- Phase Change Systems: Leverage latent heat for maximum thermal efficiency.

- AI-Driven Thermal Management: Uses machine learning for real-time optimization.

The demand for these solutions has exploded as technology pushes thermal limits. The Nvidia GB200 AI chip, for example, projects a 2,700-watt power draw, while quantum computers require temperatures near absolute zero. Traditional cooling cannot handle these extremes.

Efficient heat transfer directly impacts energy use, system reliability, and operational costs. Advanced solutions can improve heat transfer by over 4 times in turbulent flow and reduce pumping energy costs by up to 25%.

Applications range from data centers and industrial waste heat recovery to everyday office equipment like laser printers, which rely on optimized thermal management for performance and longevity.

The Core Principles of Advanced Heat Transfer

Understanding advanced heat transfer solutions requires a grasp of fundamental physics. At the core is the second law of thermodynamics, which dictates that some energy is always lost as waste heat. The goal of advanced solutions is to minimize this loss and work with natural laws, not against them.

Engineering becomes complex with multiphase flow—where different phases like liquids and gases interact at microscopic scales or under extreme pressure. Processes like boiling and condensation move enormous amounts of energy but introduce challenges like unpredictable flow patterns that can damage equipment.

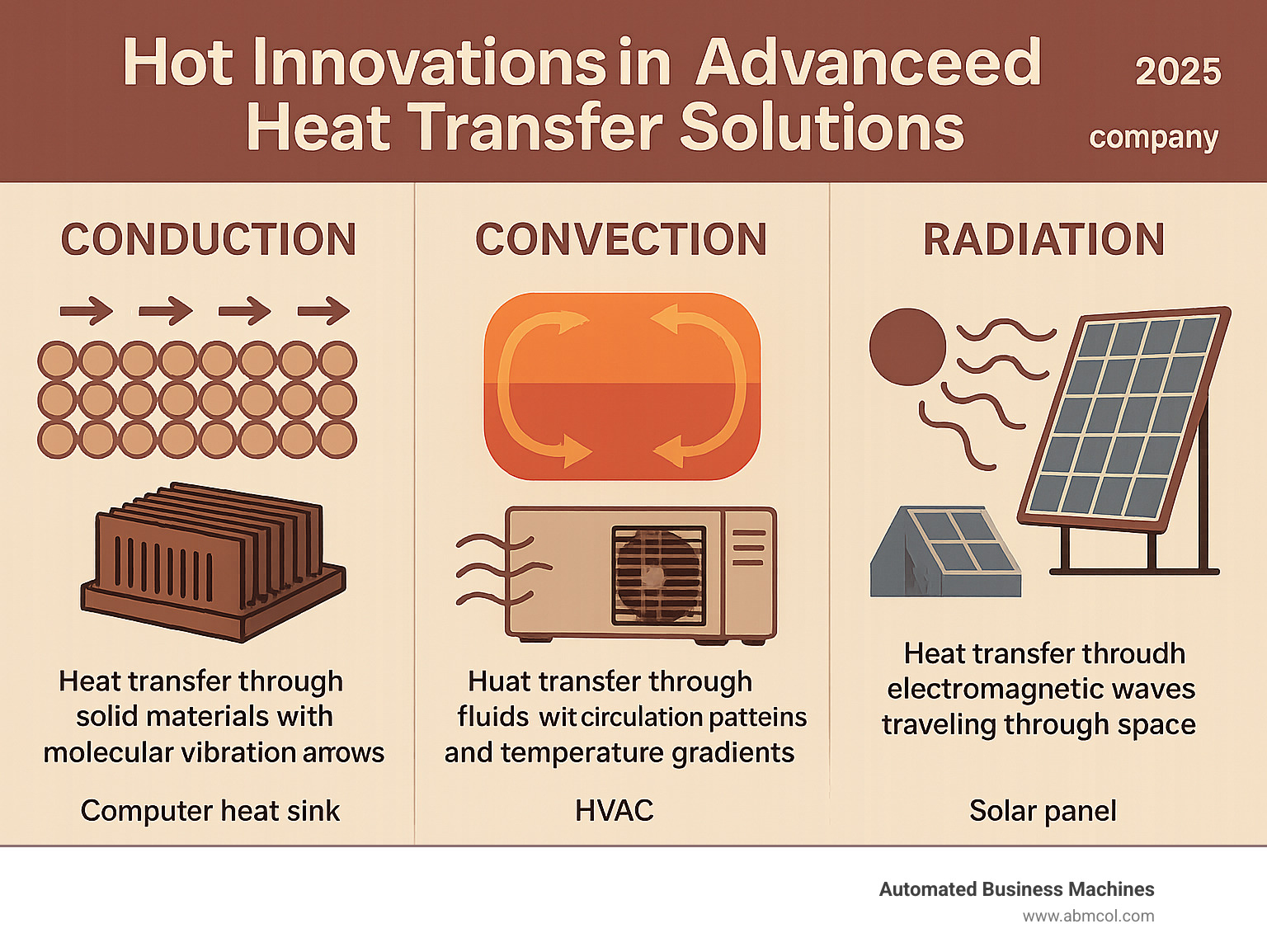

How Conduction, Convection, and Radiation Drive Advanced Systems

The three modes of heat transfer—conduction, convection, and radiation—work in concert. The best thermal solutions harmonize all three.

- Conduction (direct contact, Fourier’s Law): Advanced systems use materials like diamond-based heat sinks for electronics or aerogels for insulation, focusing on minimizing thermal resistance at contact points.

- Convection (fluid movement, Newton’s Law of Cooling): Modern systems manipulate fluid flow, creating turbulence in microchannels to maximize heat removal, often guided by computational modeling.

- Radiation (electromagnetic waves, Stefan-Boltzmann Law): Crucial at high temperatures or in a vacuum, this mode is controlled with specialized surface coatings to manage heat emission.

Optimizing these interactions is key to peak performance.

The Critical Role of Phase Change and Multiphase Flow

Phase change is a thermal superpower. When a substance like water boils, it absorbs immense latent heat without changing temperature, moving far more energy than simple heating. However, managing processes like boiling and condensation requires careful engineering to avoid reducing efficiency or creating dangerous pressure buildups.

Multiphase flows—mixtures of different phases—add complexity, such as droplet dynamics in spray cooling. Modern refrigeration cycles, for instance, depend entirely on precisely controlled phase changes of a refrigerant.

These principles impact system design across industries. Carbon capture, for example, needs stable temperature control that advanced solutions provide. Whether for computers or industrial processes, understanding these phenomena is essential. Our Heat Transfer for Polyester Guide explores these principles for specific materials.

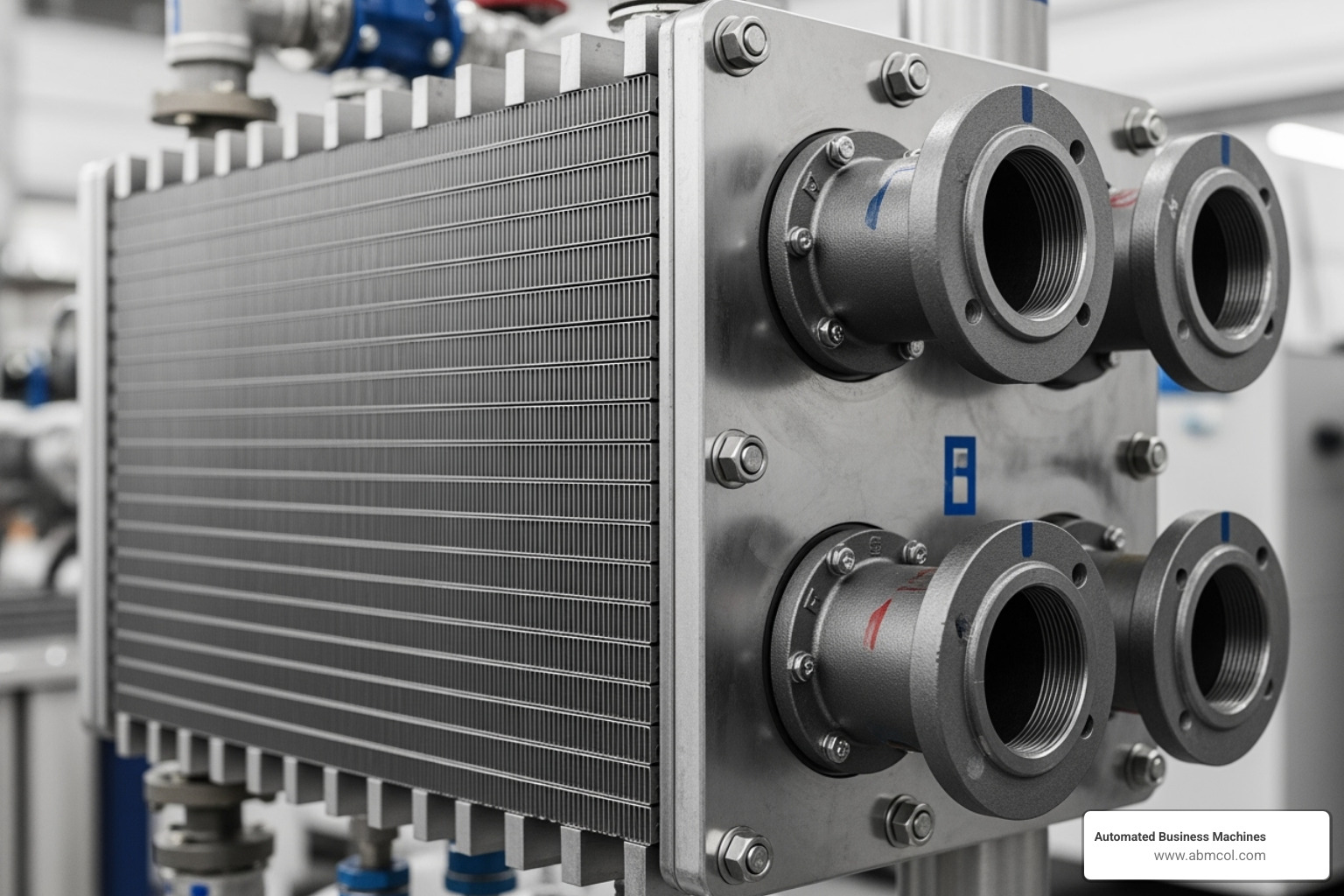

Breakthroughs in Heat Exchanger Technology

Heat exchangers are the heroes of thermal management, working in everything from HVAC systems to data centers. Advanced heat transfer solutions have transformed these devices into highly efficient machines that handle tough challenges like viscous fluids and energy recovery in a fraction of the space. This same technology helps office equipment like laser printers and digital signage run smoothly without overheating.

Comparing Heat Exchanger Designs

Different designs excel in different situations, highlighting the impact of advanced heat transfer solutions.

| Feature | Shell and Tube Heat Exchanger | Plate and Frame Heat Exchanger | Microchannel Heat Exchanger |

|---|---|---|---|

| Size/Footprint | Large, bulky | Compact, modular, expandable | Extremely compact, 4 to 6 times smaller and lighter than conventional designs |

| Efficiency | Moderate, can be limited by low turbulence | High, excellent for liquid-liquid, counter-flow | Very high, exceptionally high heat transfer coefficients due to small channels |

| Pressure Hdlg. | Moderate to High (up to 16 bar for glass-lined versions) | Moderate (gasket limits) | Extremely high, up to 1,250 bar (18,125 psi) |

| Temp. Hdlg. | High (up to 230°C for glass-lined versions) | Moderate (gasket limits) | Very wide range, from -253°C to 900°C |

| Fouling Resist. | Can be prone to fouling with viscous fluids | Can handle some fouling, wide-gap versions available | Excellent, dimpled designs prevent fouling by inducing turbulence, some are self-cleaning |

| Maintenance | Can be complex to clean, often requires significant downtime | Easier to clean and maintain, plates can be removed | Low maintenance due to anti-fouling properties, robust design |

| Applications | General industrial, chemical, oil & gas | HVAC, food & beverage, chemical, pharma | High-performance computing, aerospace, automotive, energy, carbon capture, hydrogen fueling |

While shell and tube designs are traditional and bulky, and plate and frame offer modularity, microchannel heat exchangers are game-changers, packing incredible performance into tiny packages.

Innovations Driving Efficiency

Clever innovations have boosted efficiency and shrunk footprints.

- Dimpled tubes: These precision-engineered indentations create turbulence, boosting capacity by up to 50% and cutting pumping energy costs by up to 25%. The dimples also prevent fouling, making the system self-cleaning.

- Tube insert technology: This retrofit solution disrupts flow inside existing tubes to improve heat transfer by up to 16 times in laminar flow and over 4 times in turbulent flow.

- Printed Circuit Heat Exchangers (PCHEs): These are stars of modern technology. Created by etching micro-channels into metal plates and bonding them into a solid core, PCHEs are four to six times smaller and lighter than conventional designs. They withstand extreme pressures (over 600 bar) and temperatures (-200°C to 900°C), reducing energy use and failure risk.

These breakthroughs represent a fundamental shift in thermal management, making advanced heat transfer solutions more effective than ever.

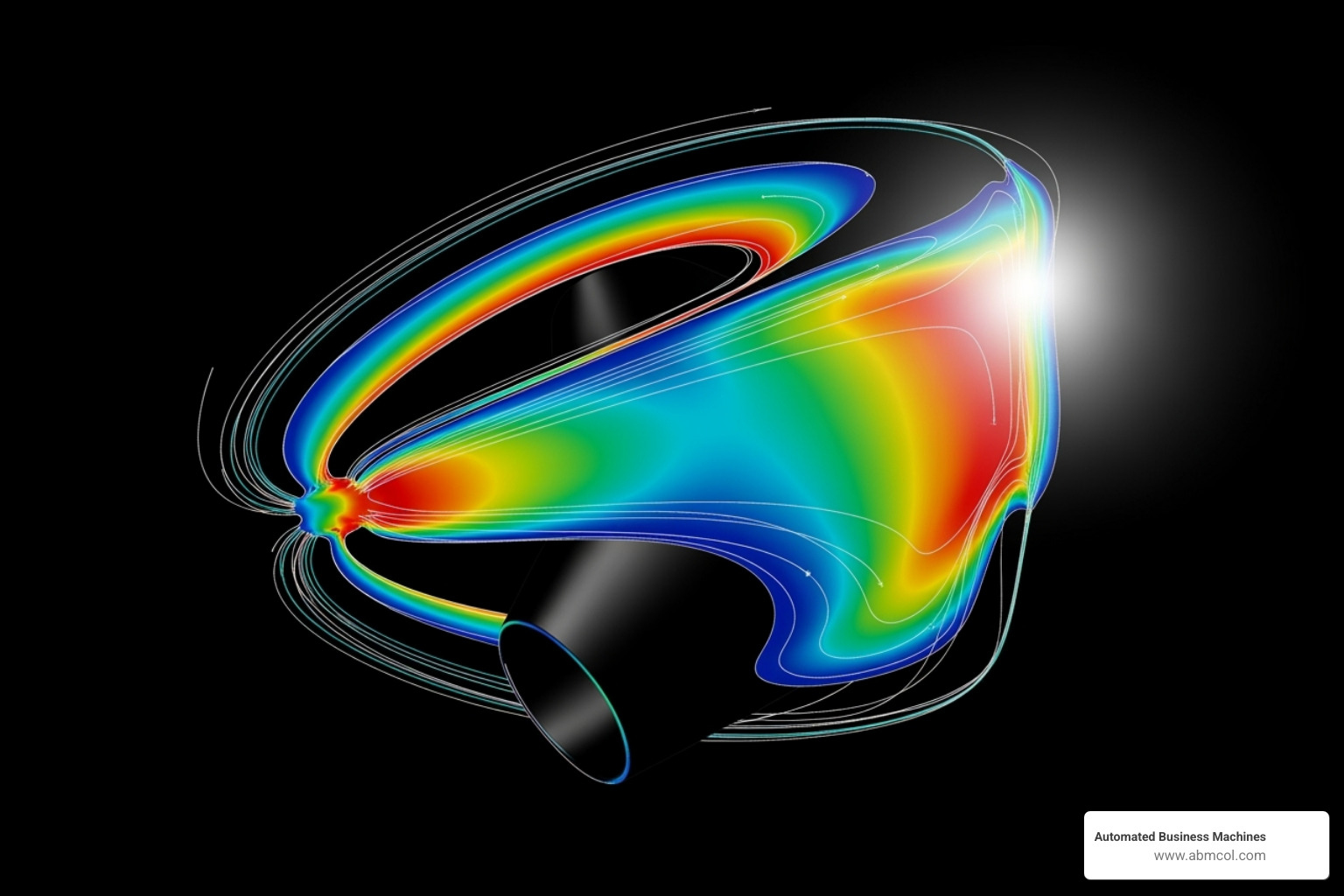

The Digital Frontier: Computational and AI-Driven Advanced Heat Transfer Solutions

The complexity of advanced heat transfer solutions requires powerful digital tools. Traditional calculations can’t handle modern designs, but computers can simulate heat flow in hours instead of years. This digital revolution allows engineers to test ideas virtually, spotting problems early and pushing the boundaries of thermal performance.

The Power of Simulation and Numerical Analysis

Computational Heat Transfer (CHT) is the backbone of modern thermal design. Using methods like Finite Element Analysis (FEA), engineers can solve complex heat flow equations before building anything. This enables:

- Predictive Modeling: Mapping temperature distributions and fluid flow with high accuracy.

- Design Validation: Testing hundreds of virtual variations to find the best solution, reducing the need for costly physical prototypes.

- Complex Geometry Analysis: Studying intricate designs like microchannels and dimpled tubes that are impossible to analyze by hand.

- Flow Visualization: Literally watching heat flow to identify hot spots and optimize patterns.

These tools give engineers the power to tackle previously impossible thermal challenges.

How Machine Learning is Revolutionizing Thermal Engineering

Machine learning is taking thermal engineering a step further. While simulation predicts outcomes for a given design, AI can explore thousands of new possibilities.

- AI-Driven Design: Algorithms propose novel geometries and materials for superior performance.

- Predictive Maintenance: AI analyzes sensor data to predict failures before they happen.

- Real-Time Optimization: Systems continuously adjust operating parameters for peak thermal performance in response to changing conditions.

- Anomaly Detection: AI acts as a watchdog, identifying unusual behavior that could signal trouble.

By combining computation and AI, advanced heat transfer solutions are becoming smarter, adapting to deliver optimal performance throughout their lifespan.

Critical Applications in Modern Industry

Advanced heat transfer solutions are essential for modern industry. From data centers to manufacturing, effective thermal management is critical for preventing system failures, improving energy efficiency, and ensuring sustainability.

Cooling the Future of Computing

Modern processors create immense heat challenges.

- AI Chips: The upcoming Nvidia GB200 chip is projected to draw 2,700 watts. Traditional air cooling is insufficient, making advanced liquid cooling and direct-to-chip systems necessary to prevent performance throttling.

- Quantum Computing: These machines require temperatures near absolute zero (50 millikelvins), colder than outer space. Complex cryogenic systems are needed to achieve and maintain these frigid conditions.

- Data Centers: Housing thousands of servers, these facilities generate enormous heat. Advanced solutions like liquid cooling and sophisticated air containment strategies are vital for managing thermal loads and energy costs.

- IoT and Edge Computing: Billions of these devices require efficient, passive cooling to ensure reliability and long battery life in diverse environments.

Enhancing Industrial and Sustainable Processes

Industries are adopting advanced thermal solutions for greater efficiency and environmental responsibility.

- Process Intensification: Advanced heat transfer enables higher yields and faster reactions in smaller equipment, saving space, energy, and materials.

- Waste Heat Recovery: Systems capture waste heat from industrial processes and reuse it, dramatically cutting energy costs and often paying for themselves within a few years.

- Chemical Reactor Cooling: Efficiently removing heat from chemical reactions is critical for safety and product quality. Specialized heat exchangers excel in these demanding environments.

- Carbon Capture: Precise thermal control is essential for CO2 absorption. Advanced heat exchangers provide the uniform temperatures needed to protect catalysts and maximize efficiency.

- Solar Thermal Energy: The efficiency of these systems depends on transferring heat from concentrated sunlight to a working fluid, a task handled by advanced solutions.

At Automated Business Machines, we know thermal management impacts all business operations. We help businesses leverage these advancements through our Digital Printing Atlanta, GA: 7 Key Benefits solutions.

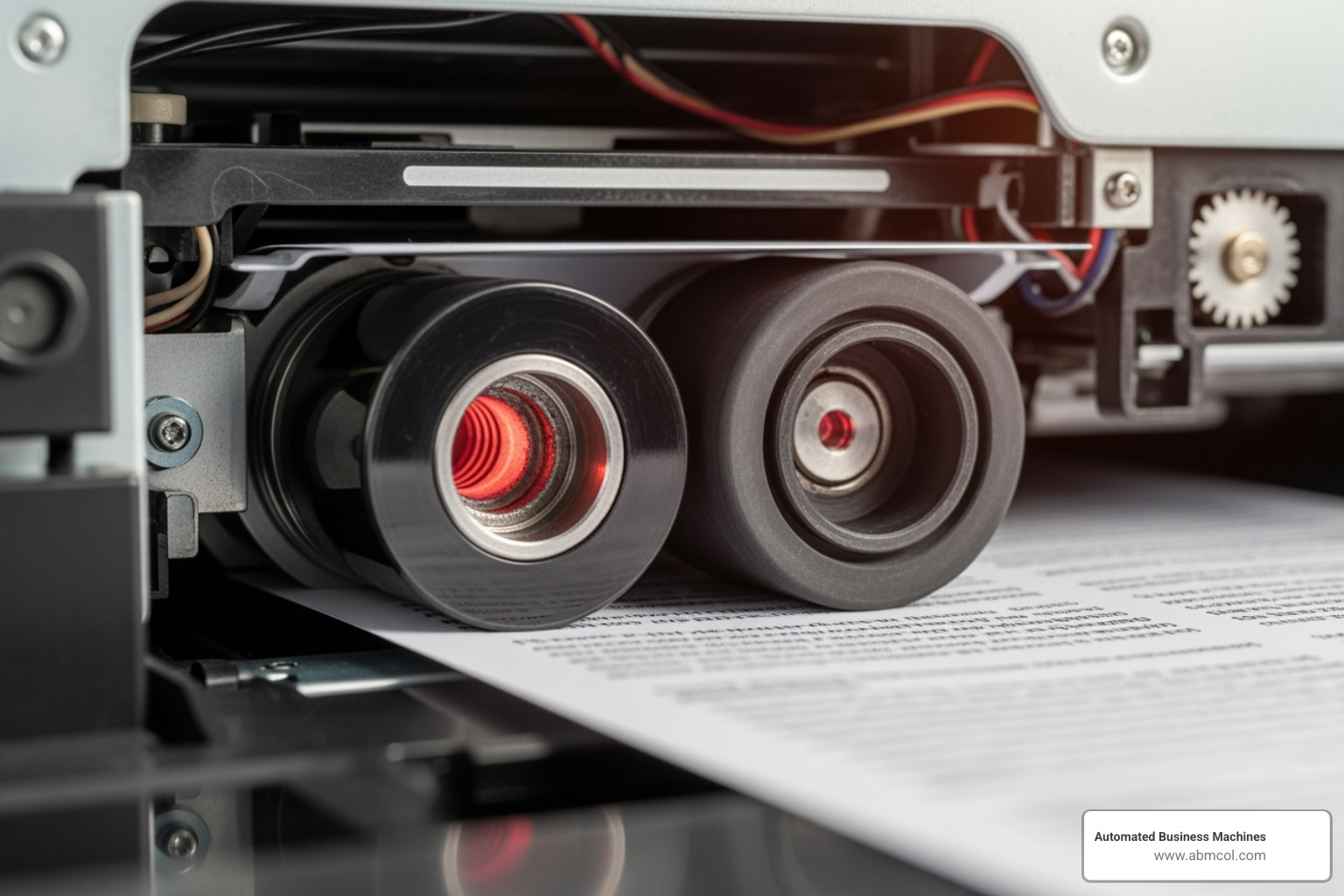

Heat Transfer in Digital Printing and Media

Heat transfer is crucial in digital printing and media, where advanced heat transfer solutions ensure perfect results. The precision needed to melt toner onto paper without scorching it is a sophisticated thermal engineering challenge.

Mastering Heat for Perfect Prints

Controlled heat is fundamental to many printing methods.

- Thermal Printers: These use heat directly. Direct thermal printers use heat-sensitive paper, while thermal transfer printers use a heated ribbon to melt ink onto paper for more durable prints. Both require precise temperature control.

- Fuser Unit Technology: In laser printers, a fuser unit uses intense heat (350-400°F) and pressure to melt toner and bond it to paper fibers. Sophisticated sensors adjust heat based on paper type to prevent scorching or jamming.

- Heat Press & Sublimation: For custom printing, heat presses transfer designs to materials like T-shirts and mugs. Sublimation is a key process where inks turn directly into a gas at high temperatures (around 375°F), permeating polyester fibers for vibrant, permanent designs. This requires incredibly uniform heat. Our guides on Heat Press Transfer Paper Types and the Best Laser Printers for Heat Transfer Paper can help you master these techniques.

Advanced heat transfer solutions for paper and media

Different media interact with heat differently, impacting print quality.

- Paper Properties: Laser printer paper is engineered to handle high heat. Paper weight and finish also matter; heavy cardstock requires more heat, while glossy paper can trap it differently. Photo paper for laser printers is specially coated to withstand high temperatures while ensuring sharp toner adhesion.

- Media Sensors: Modern printers use sensors to detect paper type, thickness, and texture, automatically adjusting thermal settings for optimal results.

- Media Compatibility: Understanding how materials like cardstock conduct and retain heat is key to professional results. Our guides can help you choose the Best Laser Printer Paper Types and Weights, the Best Photo Paper for Laser Printers, and the Best Laser Printers for Cardstock Printing.

These background thermal solutions turn complex engineering into simple, reliable printing.

Frequently Asked Questions

What are advanced heat transfer solutions?

Advanced heat transfer solutions are technologies that go far beyond traditional heating and cooling. They focus on maximizing efficiency, minimizing energy waste, and enabling high-performance operation. Key examples include microchannel heat exchangers that are 85% smaller than conventional units and dimpled tube technology that can boost heat transfer by up to 16 times. They are “advanced” because they leverage computational simulation and AI for design and real-time optimization, allowing for unprecedented performance in miniaturized packages.

How do these solutions contribute to sustainability?

These solutions are game-changers for sustainability. They contribute by:

- Recovering Energy: Advanced systems capture industrial waste heat and reuse it, dramatically cutting energy consumption.

- Increasing Efficiency: More efficient designs, like those that reduce pumping energy by 25%, directly lower emissions and fossil fuel use.

- Enabling Green Tech: They are essential for emerging technologies like carbon capture and solar thermal power, which require precise thermal control to be effective and economical.

How is heat transfer critical for modern electronics?

Heat transfer is vital for the performance and survival of modern electronics. Without it, powerful devices would quickly fail.

- High Power Density: AI chips can generate over 2,700 watts of heat, requiring advanced liquid cooling to prevent damage and thermal throttling (performance slowdowns).

- Reliability: Heat accelerates the aging of electronic components. Proper thermal management extends the lifespan of devices.

- Extreme Requirements: Quantum computers need cryogenic cooling to temperatures near absolute zero to function. Even office printers require good thermal management for tasks like printing on heavy paper. Our guide on the Best Laser Printers for Cardstock Printing offers more insight.

Conclusion

We’ve seen how advanced heat transfer solutions are revolutionizing everything from quantum computers to office printers. These intelligent technologies are not just cooling systems; they are enablers of modern technology, packing immense performance into smaller spaces and using AI to predict and prevent failures.

These solutions touch every part of our lives, from the smartphone in your pocket to the data centers that power the internet. They also drive sustainability, with significant energy savings and by making green technologies like carbon capture more efficient.

As a locally owned business serving communities across Georgia, from Albany to Savannah, Automated Business Machines knows that the best solutions are customized to your needs. Just as thermal solutions are custom to a specific challenge, we customize our printing and digital signage services to improve your productivity.

The future is exciting, with AI-designed components and new materials making thermal management more efficient. Understanding these principles can help any business make better decisions about equipment and energy costs.

Ready to optimize your printing setup? Explore our complete guide to printer paper types and sizes to see how the right materials can improve your results.